Almost every day in the news we hear of challenges in the Supply Chain. In addition to the Suez Canal blockage, covid has closed major ports in China. Reading the news, quotes like the following have become all too common: “in a string of disasters we’ve seen plague the global supply chain.”

Lately, we are seeing supply chain delays not only for necessary supplies like towels but also in silicon chips and parts.

The fact is that the Supply Chain is very complex and Covid-19 has further exposed many of its vulnerabilities.

In this third post, we delve deeper into the Digital Transformation of the Supply Chain and Logistics. What do we mean by “Digital Transformation”, especially as it applies to Supply Chain and Logistics?

As you know, many organizations have realized they need to accelerate their Digital Transformation strategies and leverage the best tools and methodologies for their journeys.

In two previous posts, we highlighted some of the essential pillars of Digital Transformation for the Supply Chain. The first blog focused on Low Code for innovations in the Supply Chain. This demonstrated that the productivity of stakeholders with Low Code platforms such as LANSA is transformative. It is one of the most important accelerators for digital transformation.

The second blog focused on legacy and ERP modernization via Omnichannel Supply Chain solutions. In a very real sense, Digital Transformation is about modernizing legacy cultures, legacy manual work patterns, legacy silos, and legacy systems of records – including ERPs. Here again, LANSA provides modern ERP systems and a Digital Transformation platform for Supply Chain innovation.

Supply Chain Digital Twins

According to Gartner. a digital twin is “a digital representation of a real-world entity or system.” Any entity can have a digital twin. This includes physical devices, connected devices, people, organizations, and, of course, processes or value streams like a Supply Chain.

A Supply Chain (SC) is a value stream. The Digital Twin of a supply chain can provide complete visibility into the entire chain. It can allow the stakeholders to drill down for more details of secondary suppliers or any phase of the complex and convoluted supply chain.

Ideally, the SC digital twin is real-time. Preferably, it also includes visual animations and monitoring. A supply chain digital twin shows the multi-tier supplier network and the flow of goods or parts.

It can also identify bottlenecks or show the status of warehouses, the transportation of parts, and distribution centers.

Check out this article to know how IBM AS/400 can improve supply chain and logistics as well as why it was created as a successor of the pre-existing platforms such as IBM System/36.

The Digital Control Center

Essentially, a supply chain DIgital Twin can be the starting point of a digital control center. This control center allows businesses to monitor, drill-down and take action – or specify digitized rules or processes to be instantiated – to remedy bottlenecks, potential adverse events, or any problem that impacts the overall performance of the Supply Chain.

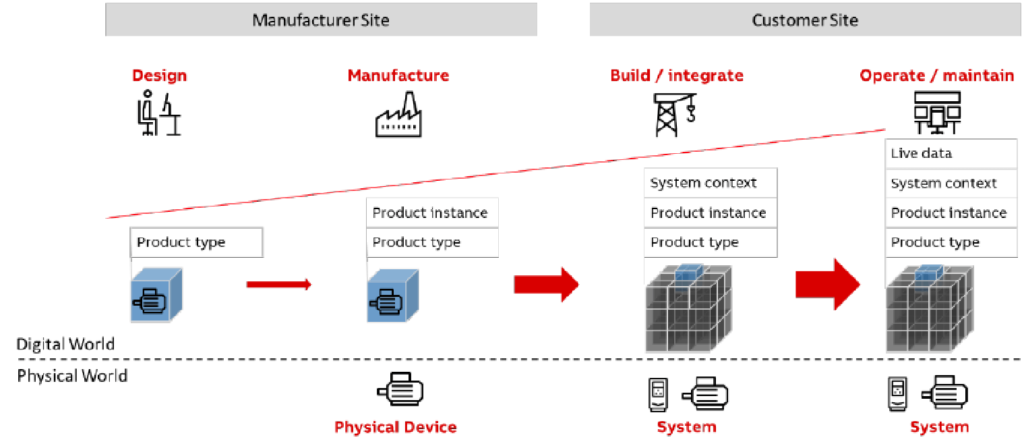

There are many advantages of having a robust digital twin for complex applications such as the Supply Chain. According to the Industrial Internet Consortium Digital Twins reduce information silos – which is critical in optimizing Supply Chains – from the manufacturers to the customers.

Internet of Things for Logistics and Supply Chain Tracking

We are living increasingly in a connected world. The Internet of Things (with its variants of both the Industrial Internet of Things and the Consumer Internet of Things) is one of the most important pillars of Digital Transformation. It has enabled innovative approaches for managing logistics and the supply chain. In this context, Logistics pertains to the distribution and organization of products within an organization. It includes warehousing, logistics, and transportation and is considered part of the overall Supply Chain.

Everything Connectected

Visibility and the robust tracking of raw materials, components, and manufactured goods to distribution warehouses are great use cases for business value from IoT/IIoT. This is especially true with analytics and the automation of end-to-end supply chain value streams.

Not only are the parts, or boxes containing parts connected — their movement and logistics tracking can also be traced via connected transportation and logistics. In the top use cases of IoT/IIoT application areas, Supply Chain Digital Transformation is perhaps second only to Digital Prescriptive Maintenance. In fact, these two use cases are interrelated, as replacement parts for maintenance typically involve the supply chain process.

Blockchain for Supply Chains

Supply Chain is the quintessential Extended Enterprise application domain. Interestingly, Supply Chain is also an ideal use case for Blockchain technologies. Blockchain can be a good backbone for the Supply Chain through several essential categories of exchanges or flows. For example, contractual flows, logistics (movement of goods and material) flows, documentation flows, and of course, the foundation of cryptocurrency, the financial transaction flow.

The digitally extended enterprise can have parts, products, suppliers, warehouses, inventory, documentation, tracing, and financial transaction masters stored on the Blockchain to function as an efficient and optimized pipeline. The decentralized and distributed Blockchain stores the same data on all its nodes. This includes data about multi-tier suppliers, parts movements, component warehousing, and, finally, delivery to customers. Blockchain stores all organizational, operational, and transactional data between the multiple tiers of the Supply Chain.

A Real-World Blockchain Example

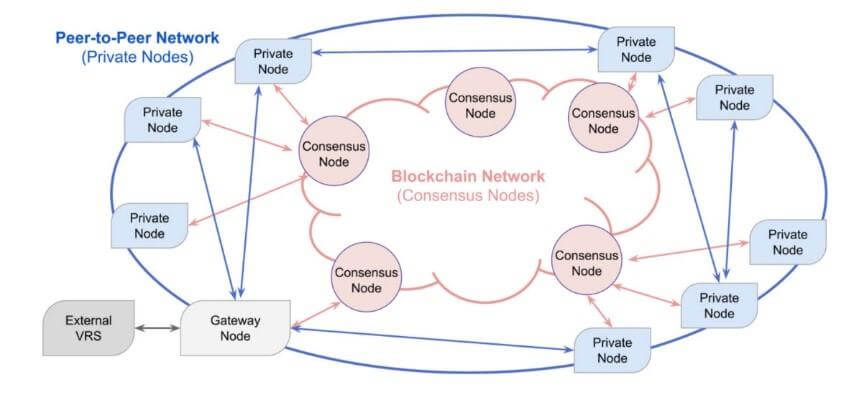

For instance, the MediLedger project started in 2017. The project leverages Blockchain specifically for the Drug Supply Chain Security Act (DSCSA). Leveraging the Blockchain as a master for drug verification is one of the essential areas addressed by MediLedger.

The following illustrates the interaction of the participating companies in the FDA pilot request DSCSA project. The Private Nodes of the participants can communicate with each other (peer-to-peer) and share data with their Consensus nodes.

Low Code Master Hub for Supply Chain Digital Transformation

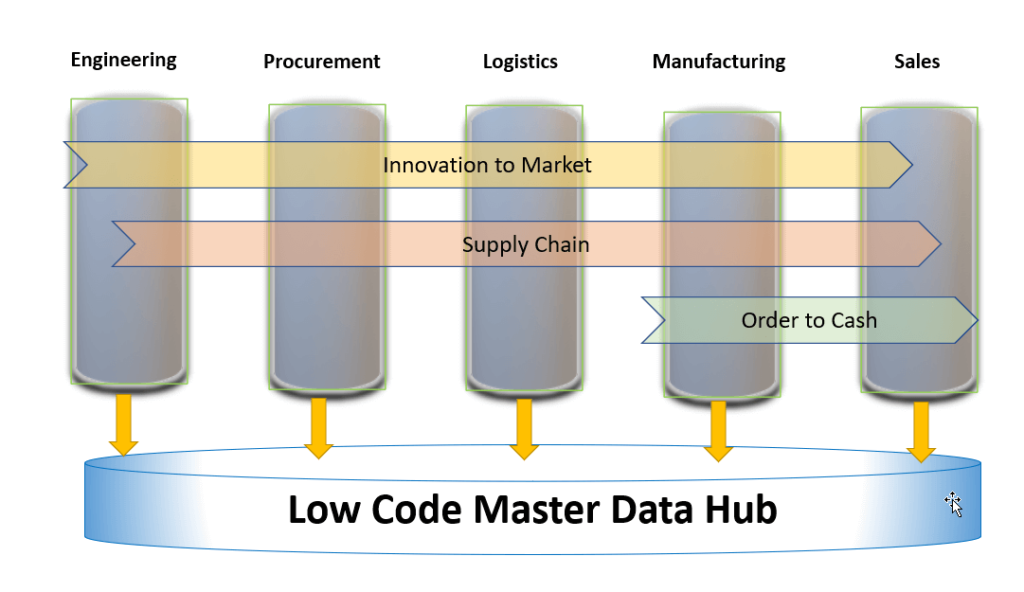

As noted above, we covered Low Code and Omnichannel Modernization of Legacies and ERPs in the previous two blogs. In fact, in the second blog, we touched upon the need of a master data strategy for Supply Chains. Every enterprise has challenges with a single version of the Truth across its business units, applications, and value streams.

Silos – in organizations, business units, and applications that they own – are the main reason there are inconsistencies in the information about the same entity: part, supplier, warehouse, transportation, product, or other. Master Data addresses several pain points. Here are a few examples:

- Inconsistencies and poor data quality result in poor, erroneous, and even risky decisions.

- Often different siloed systems contain contradictory information about the same entity. There is a lot of waste attempting to keep heterogeneous data consistent and of high quality.

- Mergers and Acquisitions also create data consistency challenges – to have a single version of the Truth about a customer or offering across the organization.

The Low-code Digital Transformation Solution

Fortunately, there is a Digital Transformation solution that can at the same time achieve the objectives of accelerated Low Code development while addressing the needs of end-to-end data integration for Supply Chains (and other enterprise application domains).

With LANSA’s robust platform and solutions, you can quickly and efficiently build end-to-end applications using Low Code. This allows supply chain stakeholders to integrate with various systems of record, leverage LANSAs own modern ERPs for Supply Chain or other applications, and most importantly achieve all the objectives of a Master Data for Supply Chain (or other) as a Digital Transformation hub without unnecessary complexity of additional platforms or tools.

LANSA’s platform also incorporates intelligent business rules for data integrity as well as business rules. Furthermore, its Low-Code service-oriented capabilities allow consumption and production of APIs (such as REST or other) with little coding. Everything is model-driven through its easy-to-use platforms and tools.

0 Comments